A TRUSTED BUSINESS PARTNER

For over 20 years, companies such as Amazon®, Caterpillar®, Dana Corp®

and Lincoln Electric® have relied on our expertise, quality, and efficiency.

Trusted by Industry Leaders

“Progressive Powder Coating is a true business partner and our ‘go-to guys’ for powder coating. They are extremely professional to work with, their equipment is state-of-the-art, and they have the quickest turnaround times of any powder coater we’ve ever used.”

-Dave O., Sourcing Engineer, Lincoln Electric®

“John and his team at Progressive Powder Coating offer extraordinary service and business ethics. They have gone above and beyond our expectations time and time again. The powder coating on all of our product lines and other projects has always been completed in a timely manner and to the exact specifications that we demand. It is rare to find such competitive pricing and quality of work under one roof. My company is very thankful to have partners like John and Progressive Powder Coating.”

-Larry D., Materials Manager

“Progressive Powder Coating has demonstrated its value to us repeatedly throughout the duration of our relationship. They successfully combine quality, accuracy, value, responsiveness, and service to enable us to deliver precisely what our customers expect when ordering painted product. They are quick to respond to all kinds of special requests and work diligently with us when trying to address problems we encounter that are inherent when working with customers in the markets that we supply. Progressive is the essence of what a business partnership should be.”

-Tom H., Plant Manager, voestalpine Roll Forming Corporation

Our Business Partners

Why Progressive Powder Coating?

5-day Turnaround

We’ve implemented efficient, high-volume processes to ensure your product gets turned around in industry-leading time: 5 days or less on average.

Custom Quality Control

We provide a custom-tailored quality program for each customer. Your product will go through multiple testing procedures, such as the Process Control Program, Gloss Tests, and Visual Color Checks, prior to job completion.

Cost Savings

Our in-house manufacturing of all tooling can significantly reduce your company’s expenses associated with outsourced tooling production. This cost-effective service also expedites the time it takes to bring your product to market.

Immediate Project Availability

We can efficiently manage a wide range of large-scale industrial projects in our 300,000 sq. ft. facility without causing any delays to your timeline. We can tailor our services to meet the specific demands of your project.

Centrally Located Facility

We are located minutes away from Interstate 90, State Route 2, and the Cleveland, OH railroad hub, making logistics easy.

Inventory Management

We can house your parts inventory, managing ordering and shipping schedules for seamless integration into your manufacturing process.

Essential Services

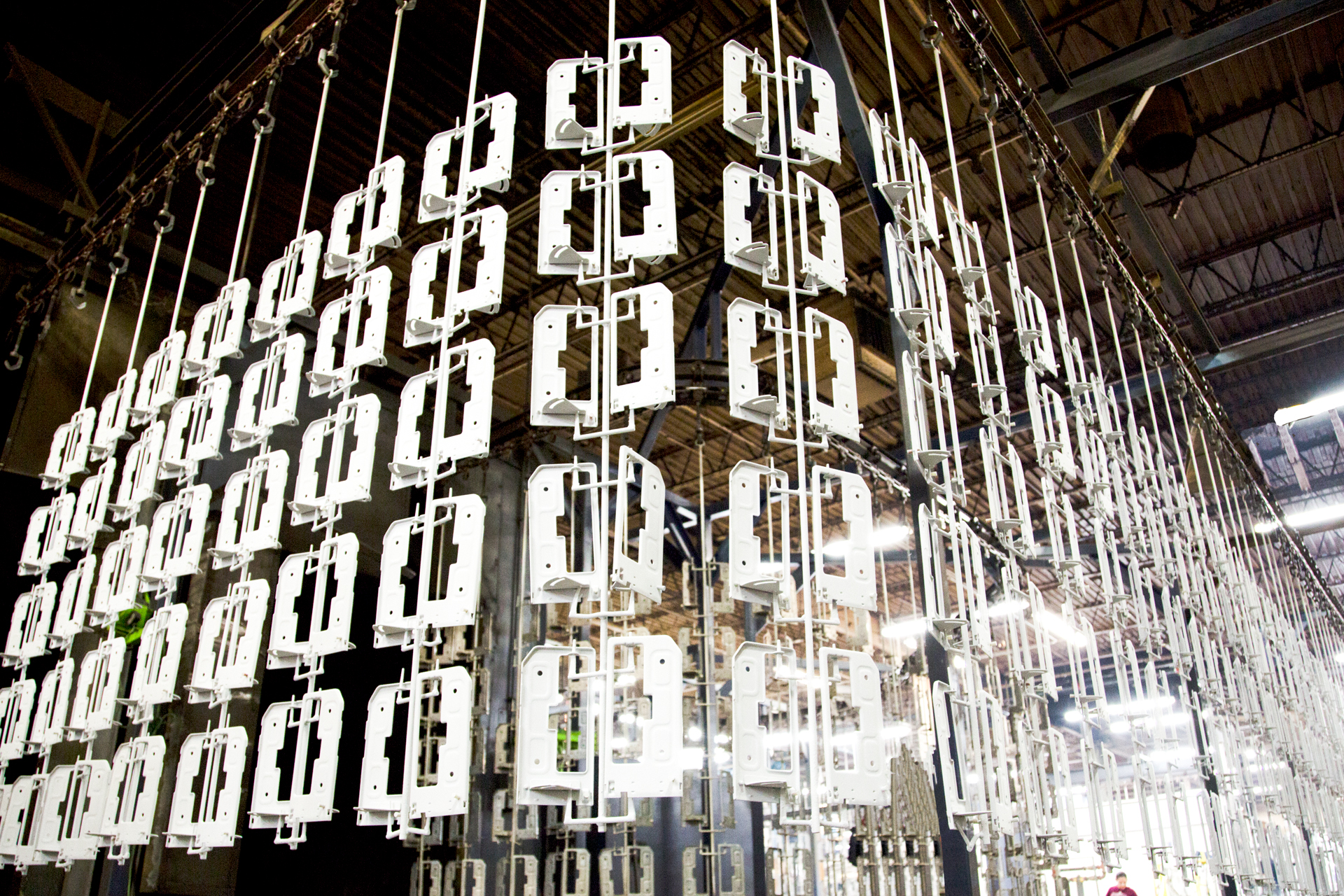

Powder Coating

Three state-of-the-art powder coating lines equipped to handle large-volume projects.

Masking & Unmasking

Custom to meet each project’s powder coating needs, eliminating potential problems down the road.

Sticker & Decal Application

Following the powder coating process, we can apply stickers, decals, and labels to each part or skid.

Sub-Assembly

We can assemble your product following the powder coating process, prior to packing.

Final Packing Off-Line

To ensure the quality and safety of your product during transit.

Drop Shipping

We can safely store your powder coated inventory and ship directly out of our Mentor, OH warehouse.

In-House Tooling Design

Ahead of the powder coating process, custom tooling for each product is designed and manufactured right here in-house.

Custom Product Solutions

Materials & Substrates

We powder coat the following materials and substrates: steel, steel castings, galvanized steel, aluminized steel, aluminum, aluminum castings, galvanneal, powdered metal, and sintered metal.

Colors

We support the RAL classic color palette, custom color matches, and all stock colors from multiple suppliers.

Finishes

We support a variety of textured type finishes.

Formulas

We can powder coat epoxies, epoxy hybrids, TGIC/polyester, polyester, urethanes, Teflon, and vinyl-like coating.

Specialties

We specialize in anti-bacterial, anti-gassing (OGF), federal standards/military, high-temperature finishes up to 1,000 degrees Fahrenheit, and marine grade specifications.

Quick Quotes & Competitive Prices

We support a vast number of industries each year, and we offer industry-leading turnaround times on jobs that we take on.